SeZaM system based on the GE Smallworld platform supports pipelines as well as telecommunications and energy networks at PERN.

About the project

PERN is a key company in Poland’s energy infrastructure. It transports oil from Russia to Poland and Germany and distributes liquid fuels around Poland. PERN’s technical infrastructure can be found all around the country and it includes oil pipelines, product pipelines, oil storage units, as well as energy and fiber optic networks.

In 2009, PERN’s management decided to implement a complex IT system for managing network assets. The company turned to Globema in search of an efficient implementation. The initial project of implementing the SeZaM system included implementing the GE Global Transmission Office application based on the GE Smallworld platform as well as creating an inventory of the transmission network, storage units, and fiber-optic network.

In the following years, the system was expanded with additional functional modules (such as managing work in the Explosion Hazardous Areas) in the Pay-As-You-Go model.

Contents:

Industry: Oil & Gas

Country: Poland

Service: GE Global Transmission Office/Smallworld

Category: Network Asset Management

PERN is one of the leading companies for oil transportation and storage in Poland. PERN manages the oil and product pipeline network. The company owns about 3.5 mln m3 of storage capacity for crude oil and about 1.8 mln m3 liquid fuel storage capacity.

PERN’s challenges and initial implementation of the inventory and network asset management system

The business goals of the initial implementation:

- Optimizing the usage of assets involved in the business and operations;

- Increasing the effectiveness of maintenance management based on risk assessment and evaluating the effects on the environment;

- Minimizing the reaction time to the unexpected events and more efficient outage management;

- Increasing the profitability and improving the effectiveness of investments in the pipeline infrastructure and storage capacity;

- Consolidating the data from different areas of company operations.

The system needed to meet particular expectations:

The key challenges of implementing the SeZaM system:

- Systems used at that time lacked the detailed technical description of devices;

- Information from many different systems, such as SCADA and ERP, needed to be combined;

- A need for presenting the data, including combined information from different systems, in the spatial context that includes landform and pipeline routes;

- A need for creating a method for a 3D approximation of pipeline positions with intelligent pigging.

Solution – the initial SeZaM system architecture

SeZaM’s key element is GE Global Transmission Office, a reputable solution based on the GE Smallworld platform, implemented by many transmission system operators around the world.

Fiber optic network management is handled by the GE Physical Network Inventory application that’s also based on GE Smallworld.

The system captured pipeline, storage base, and fiber optic network data.

The process of outage management is supported by finding the outage location with reflectometric measurements as well as determining the affected resources and alternative routes.

Other than the geographic frame of reference, the system provides route mileage for linear segmentation and anomaly browser based on data from the intelligent pigging.

The spatial analysis was expanded with the capacity analysis and gravitational pipeline emptying. This was possible due to adding the option to model the pipeline course and presenting longitudinal profiles.

To improve telecommunications operations, we implemented tools for modeling network availability within the optic fibers, supporting automatic service routing, and visualizations in the field.

The system captured static data from many external sources and paper documents and it was connected to map services from a Polish geodetic web service, Geoportal.

The storage bases were supplied with internal schematics and topologically connected to the network.

SeZaM was integrated with SAP and SCADA systems.

Solution – the SeZaM system functional development

The success of the initial SeZaM system implementation meant that it is seen as an answer to the new needs and requirements of PERN. Those stem from the business changes as well as internal company decisions about implementing and improving new processes.

The needs that trigger system development

- Organizing and managing real estate and land easement on the pipeline course;

- Supporting maintenance process;

- Improving the outage management within pipelines and the fiber optic network;

- Managing the pipeline capacity;

- Improving the accuracy of determining the amount of fuel needed for pumping;

- Improving the management of Explosion Hazardous Areas (Ex Zones);

- Managing the internal energy network;

- Initiating the new business process operations:

- Shutting down devices

- Device damage handling

- Modernization support;

- Supporting fieldwork such as inspections, maintenance, or diagnostics;

- Including an incorporated company, Liquid Fuels Logistic Operator LLC, into the system.

Expanding the SeZaM system

To meet the needs of the parcel easement, maintenance, modernization, device discontinuation, as well as outage and damage management, we implemented special modules that were adjusted to PERN’s requirements. We created a new module for the unique requirements of Ex Zone management. Additionally, we created an interface with a system for handling pumping to support pipeline capacity management and determining the amount of fuel for pumping.

To support the management of the fiber-optic network, we implemented the fiber monitoring system. To precisely determine capacity, we needed to expand the database with information about device volumes and supplement pipes inside the objects as well as introduce the pipeline segmentation for the system for handling pumping. Therefore, the SeZaM system became the most reliable source of data about capacities.

The internal energy network was modeled in the EL.GIS/Smallworld system used by the Distribution System Operators. The model included a medium and low voltage network and the EL.GIS system was adjusted to PERN’s needs. All three solutions (for crude oil transfer, telecommunications, and energy) were built on the same Smallworld platform, using the same database and licensing model. This reduced the solution cost and its operational costs.

The data from different business areas are easy to access by anyone who needs them and the user experience is the added value to the company. Managing such a complex solution is easier when it’s done through a single platform with an integrated database.

The architecture of the Network Asset Management system implemented at PERN

Support for field service and field workforce employees

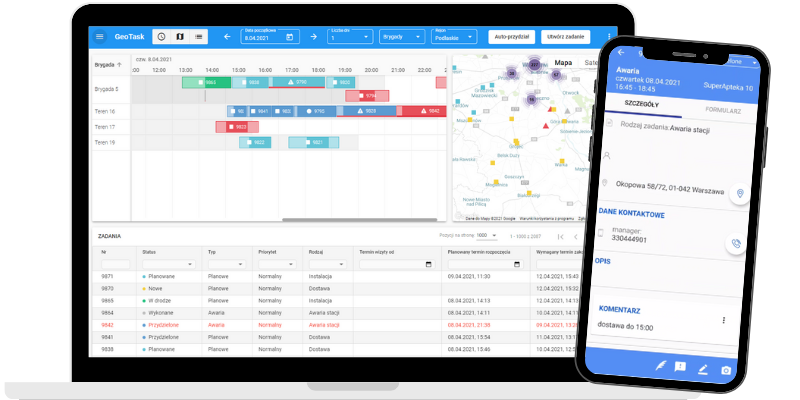

Support for field service and field workforce employees was handled by a separate Mobile Workforce Management solution, GeoTask. It supports operations such as inspections, maintenance, device diagnostics, and Ex Zone management.

Each task is prepared in the SeZaM system based on the collected data. Then the tasks are forwarded to the dispatchers via the GeoTask application. The application distributes tasks between the field workforce teams based on optimization algorithms.

The teams use mobile devices with the NFC (Near-Field Communication) technology that makes it easy to register work in different objects. The data collected in the field is forwarded back to the SeZaM system to always stay up-to-date.

The inventory process and data capture

Other than implementing the network inventory system with additional modules, we also captured data from different sources. The data migration included:

- Pipe infrastructure

- Telecommunications infrastructure

- Energy infrastructure

Benefits

Implementing the SeZaM system provided PERN with complex support and improvement of maintenance processes and network operations through:

Organizing the data and building topological models of the pipeline, fiber optic, and energy network that provides:

- Convenient access to up-to-date information at the map level as well as attribute searching for everyone involved in the process,

- Possibilities for spatial location of objects and events,

- Elimination or reduction of paper document usage.

Integration with other systems (SAP, SCADA, ONMS, pumping handling) that gives:

- Easy access to all the needed information in a single place,

- Possibilities for performing cross-sectional analyses and reports,

- Automation of work and improving its quality,

- Improvement of the business process flow.

Data consistency and reliability

System support for the process standardization

Summary

Choosing the renowned GE Smallworld platform with its support from one of the largest solution providers for the utilities has guaranteed implementation success. It allowed PERN to constantly develop, meet arising business needs and tackle challenges over the years. During the 12-year collaboration, the Pay-As-You-Go model for the system development turned out to be very efficient. Each module and integration was implemented as an answer to a new business need. Only then the company had to cover its cost. The SeZaM system, together with the SAP system, is a critical tool for PERN operations.

Discover other success stories

Network Inventory System for years – Smallworld in Netia

Learn how for the last 20 years, Smallworld has been helping Netia develop the network, manage the infrastructure, and introduce cutting-edge services.

Network inventory supports Polenergia’s growth based on M&A

Learn how we standardized the network management at one of the largest energy distributors in Poland and organized data about 30 areas covering 11 thousand customers.